FRUIT WASHING WAXING DRYING AND GRADING PRODUCTION LINE FULL SOLUTION:

Introduction

Fruit waxing is the process of covering fruits (and in some cases vegetables) with artificial waxing material. Natural wax is removed first, usually by washing. Waxing materials may be either natural or petroleum-based.

The primary reasons for waxing are to prevent water loss (making up for the removal in washing of the natural waxes in fruits that have them, particularly citrus but also, for example, apples and thus retard shrinkage and spoilage, and to improve appearance.

Dyes may be added to further enhance appearance, and sometimes fungicides.

Fruits were waxed to cause fermentation as early as the 12th or the 13th century; commercial producers began waxing citrus to extend shelf life in the 1920s and 1930s. Aesthetics—consumer preference for shiny fruit—has since become the main reason.

In addition to fruit, some vegetables can usefully be waxed, such as cassava; vegetables commonly waxed include cucumbers, swedes or rutabagas and green tomatoes.

A distinction may be made between storage wax, pack-out wax (for immediate sale) and high-shine wax (for optimum attractiveness).

The waxing materials used depend to some extent on regulations in the country of production and/or export; both natural waxes (sugar-cane, carnauba, shellac, or resin) or petroleum-based waxes (usually proprietary formulae) are used. Wax may be applied in a volatile petroleum-based solvent but is now more commonly applied via a water-based emulsion.

Blended paraffin waxes applied as an oil or paste are often used on vegetables.

*- According to Wikipedia.

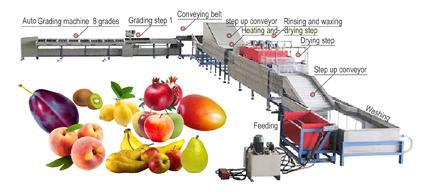

Production line operations:

1. Deep fruits cleaning.

2- Drying and waxing for fruits processing.

3- Dry the fruit completely

4- Grading fruits according to size or weight:

A- Size grading: for grade and sort the spherical shape approx fruit and vegetables by size, such as orange, grape fruit, dates, garlic, onion, tomato, potato and so on.

B- Weight grading: to grade fruit and vegetables by weight.

Adopt the balance to weight each fruit or vegetable one by one, and the accuracy of grading machine is up to 99%. Besides, with great gentleness it preserves the integrity of fruit and vegetables.

It is appropriate for apple, pear, dragon fruit, pomegranate, mango, peach, kiwi, pineapple, potatoes, persimmons, and so on.

Useing: It is required to have a place divided into three sections: the raw materials section up to 400 meters at least, and the finished materials section up to 500 meters at least. Production hall up to 200m, all these sections should be has place for discharge and loading the containers.

Workers: 10 workers is enough.

Grade: 8 grades,8 compartments.

Production capacity: 15000-21000 Fruits per hour

Total power: 5.8KW

Dimensions:

Straight length: 26100mm "26.1 Meter".

U shape: 1: Feeding: 4500 mm, 2: step up conveyor + drying step + rising and waxing + heating and drying step + step up conveyor 12200mm "12.2 Meter", 3: conveyor belt + grading step 1 + auto grading 9400mm "9.4 Meter".